Umachines Claims 2D MEMS Advance

With a new take on 2D MEMS, this startup enters the swelling ranks of the multidimensional MEMS wars

March 14, 2002

Component startup Umachines Inc. plans to use the upcoming Optical Fiber Communication Conference and Exhibit (OFC) to showcase its particular take on MEMS (micro-electro-mechanical systems).

Umachines is part of a growing roster of companies lining up in favor of 2D versus 3D MEMS (see Umachines Unveils MEMS Switch and Umachines Is Wild About MEMS). Unsurprisingly, the startup says its take on 2D MEMS sets it apart from the rest.

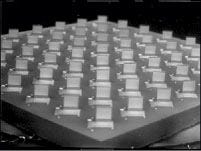

Putting this claim into perspective requires some definitions: MEMS is a technique wherein arrays of tiny tilted mirrors are used to shunt light in various directions. Two basic types of MEMS arrays are in use today: 2D MEMS, wherein the multiple mirrors are arrayed on a single level, or plane, in an optical component (see All-Optical Switching Tutorial, Part 2); and 3D MEMS, in which the mirrors are arrayed on two or more planes, allowing light to be shaped in a broader range of ways. In general, 2D MEMS is thought to be cheaper and easier to make than 3D, but it supports a smaller switch port count.

Both 2D and 3D MEMS call for the tiny mirrors to hinge up and down at specific angles in order to direct light through a switch. Therein lies much criticism of MEMS technology in general: The wear and tear caused by moving parts leads to quick obsolesence. And getting the mirrors to angle just right requires very complex controls.

Now Umachines says it's got a way to overcome both these negative factors. Instead of moving the mirrors horizontally to direct light, the vendor permanently sets the angle of the mirror in the manufacturing process. In the finished module, the mirrors move vertically into the path of the light. No angles, no hinges.

This setup, Umachines claims, makes its MEMS hardier and easier to manufacture. "We believe that our [technique] has enabled us to manufacture components that have superior performance and reliability," says Cheng Teik Tan, VP of business development at Umachines. He touts a recently signed manufacturing contract with Sanmina-SCI Corp. (Nasdaq: SANM) as evidence of the startup's fabrication viability.

Is Umachines's take really unique? It's tough to tell. Competitors such as OMM Inc. seem indifferent to news of the innovation.

"Let me say this: We've been around for five years, we ship to over sixty customers. I think anybody coming into this market has a long, tough battle ahead," says Conrad Burke, senior VP of sales and marketing at OMM.

Burke says that over the next couple of years, market demand will focus on smaller-port-count switches for edge and metro use, not massive all-optical crossconnects. Customers are eager for modules featuring up to 32x32-wavelengths, he says.

Like Umachines, OMM has decided on 2D MEMS, since 3D technology is still "expensive and unproven," according to Burke. OMM abandoned its 3D MEMS development plans last year (see OMM-inous News), believing the market was farther out than originally hoped.

The roster of companies joining the 2D march is growing, bolstered by financial conditions that force a choice between the technologies. Like OMM and Umachines, DiCon Fiberoptics Inc. sees lots of life in 2D MEMS (see DiCon Intros 11 New Products ).

This isn't to say 3D has entirely lost its luster. Agere Systems (NYSE: AGR) says its primary focus is on 3D MEMS (see Agere Ramps Up 3D MEMS). Movaz Networks Inc. announced yesterday it will demo its own 3D MEMS module at OFC (see Movaz Sees 3D), and Integrated Micromachines Inc. (IMMI), whose founders are friendly with OMM's, plans to unveil its new 80x80-wavelength 3D MEMS switch at the show.

Last August, IMMI opted to get out of 2D MEMS development. CEO Denny K. Miu claims it was a coincidence that his buddies at OMM got out of 3D MEMS just prior to this decision. But he does concede, "We didn't want to compete with OMM and others for low-port business."

Miu says the key to the 3D market is making an optical switch module that can add to, rather than replace, existing OEO switches. "Our customers want to augment what they already have," he says. Relatively small but scaleable optical switches based on 3D MEMS are just the ticket for equipment vendors looking to add high-speed core connectivity to existing multiservice gear, he maintains.  — Mary Jander, Senior Editor, Light Reading

— Mary Jander, Senior Editor, Light Reading

http://www.lightreading.com

You May Also Like