Nokia offers rare glimpse of its northern lights

At its Oulu facilities on the edge of Lapland, Nokia is pushing 5G and 6G technologies to the very limits.

Catch an hour-long flight north out of Helsinki and you arrive in Oulu, on the doorstep of Lapland. The setting, at this time of year, is a frosty coastal plain of scattered low-rise buildings and pine trees furred with snow, where the temperature sits uncomfortably under zero by a few degrees Celsius. The world's northernmost city outside Russia, Oulu is associated in the minds of foreigners with the Aurora Borealis, cross-country skiers, sauna enthusiasts, a diet of reindeer meat and sightings of stray Christmas elves. But it's also home to one of the most important technology centers in the world – a 3,000-employee wireless facility operated by Nokia.

The telecom equipment vendor, a Finnish national champion, carried out its first research-and-development (R&D) project there some 50 years ago. Since then, Oulu has become integral to Nokia's entire mobile business. And humanity's addiction to smartphones, often running on networks that Nokia designed, makes it critical outside the company. Take Oulu with its hundreds of experts off the map and the planet would have a problem.

It is an unusual place, and not just because of its bleak surroundings on the edge of the Arctic Circle. Jarkko Pyykkönen, the head of the Oulu technology center and Nokia's supply chain, says it is the only location where Nokia combines R&D, testing and production under one roof. He doubts Nokia's key rivals have anything quite like it, either. "This is a unique setup," Pyykkönen told reporters invited on a tour of the premises this week.

Dubbed the "home of radio" by Nokia, it has contributed to the development of wireless telecom since the days of first-generation mobile. More recently, the focus has obviously been on 5G and what follows. And the complexity of these 5G and 6G systems explains the nature of the evolution seen at Nokia's testing facilities.

Inside the grotto

Much of the expertise at Oulu is concentrated in an advanced 5G technology called "massive MIMO." More basic radios come with just a handful of transmitters and receivers. Massive MIMO configurations include dozens. Through a technique known as beamforming, those radios can shoot a signal at an end-user device with sniper-like precision. But with so many advanced components and mind-boggling algorithms in use, even the tiniest issue can produce a miss.

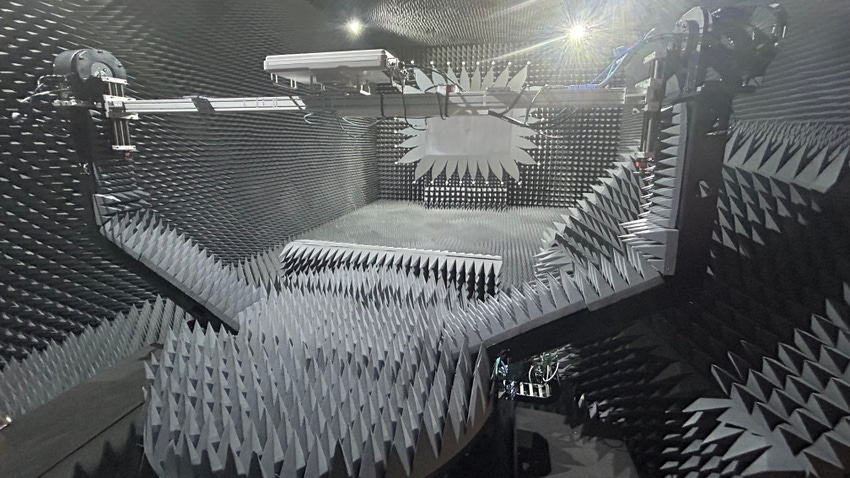

Hence some of the correspondingly massive investments Nokia has made in its over-the-air validation area (OTAVA, for short). Throughout a sprawling campus, Nokia has retrofitted shipping containers – each emblazoned with its logo – to support tests on radiofrequency (RF) and antenna equipment. To the uninitiated, the insides of these containers look bizarre. Bristling from corner to corner with greyish foam spikes, they have the sinister appearance of a medieval torture chamber. The basic idea, though, is to cancel out noise.

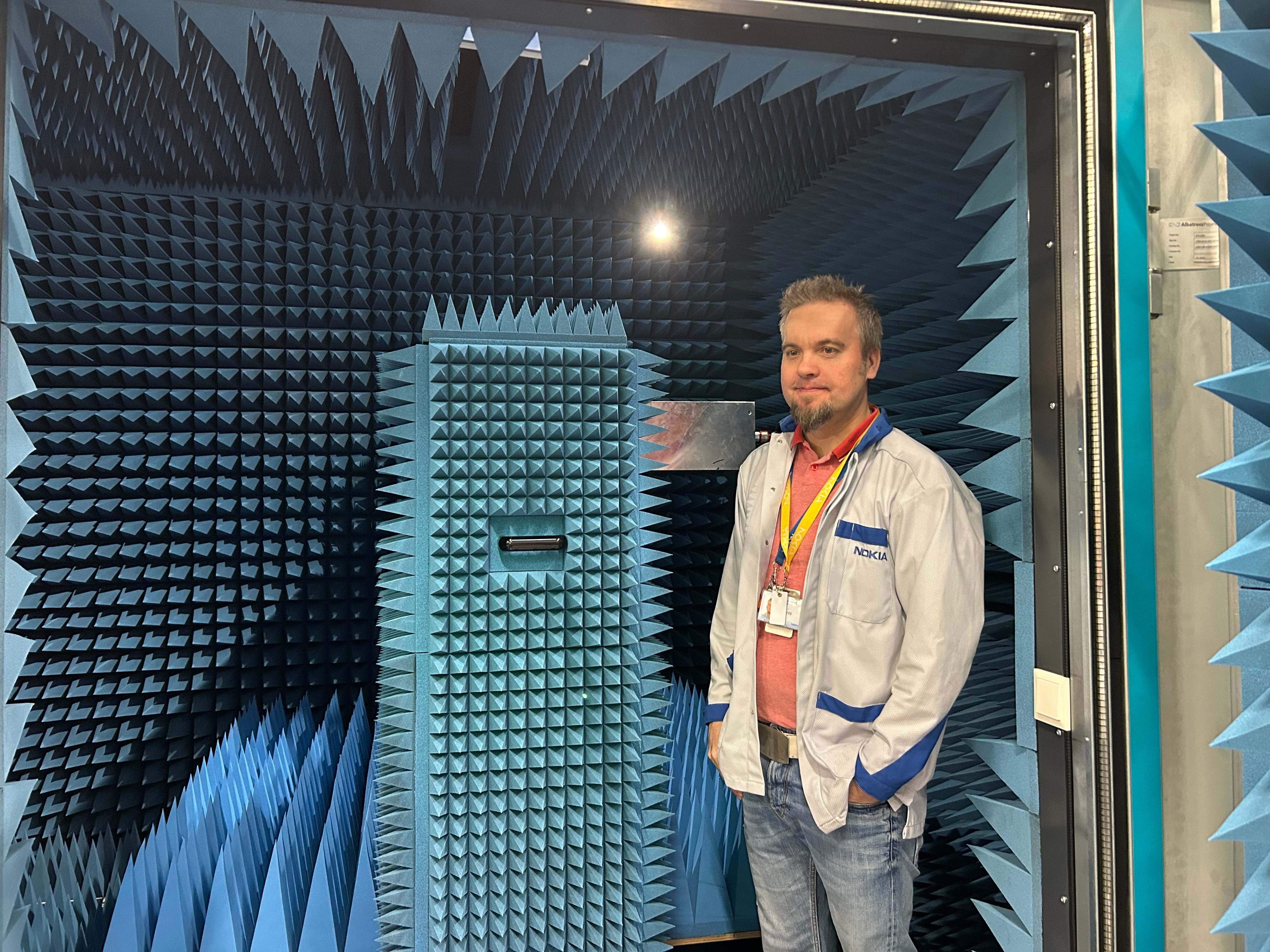

A Nokia employee prepares for some wireless torture in Oulu. (Source: Iain Morris/Light Reading)

"For most of the RF measurements, you want to have the anechoic room so it will absorb all the radiation," explained Mikko Laamanen, Nokia's verification director. "You don't hear the reflections from the walls." With the sheer variety of chamber sizes, radio equipment and software tools on display, Nokia has been able to run tests across numerous frequency bands on all configurations – from the most basic 5G radios to the units with 64 transmitters and receivers (so-called 64T64R) that some operators have already deployed.

The latest innovation, highly secret until now, is Nokia's 360-degree wall. Opened in the second half of this year, it has remained off-limits to most outsiders and Nokia is understandably guarded about the details. Unlike in other parts of OTAVA, reporters were forbidden from taking photos of the actual wall or even slideware describing it. But picture a circular chamber, as opposed to the squarish shipping containers, where the anechoic, iron maiden spikes are interspersed with small antenna units for pinging signals around. This way, Nokia can emulate the conditions found in more challenging mobility environments.

"By having those antennas and cables, we can connect any mobile to any of these antennas and start moving it from one antenna to another," said Ikonen Marko, Nokia's verification director for RF beamforming. "We can simulate and mimic the use case for example where we have a high-speed train." Onsite equipment allows Nokia to measure power radiated by each antenna at any given time and ensure beams are correctly formed and not radiating in unwanted directions, added Laamanen.

The wall can run tests in spectrum bands ranging from 600MHz to 7.125GHz, and one of the company messages is that it will figure prominently in Nokia's early work on 6G. Among other things, there is talk by Finnish executives of going far beyond the 64T64R configurations, right up to units including 256 elements.

Hard act to follow

For any visitor conscious of worldwide efforts to nurture competition to Nokia, a big takeaway is just how hard this would be for almost anyone to replicate. And without testing and verification, Nokia would not have the data it needs to fine tune its algorithms for optimal performance. Rivals forced to skip these steps or take economical shortcuts risk falling behind in the field.

The cost and scale of it is, of course, an overarching factor. A single, signal-boosting mirror installed in one anechoic chamber apparently came with a six-digit price tag. Between 2016 and this year, Nokia added 37,100 square meters of space for OTAVA laboratory expansion as it pushed into 5G Advanced and 6G research. By 2024, it plans to add another 13,500 square meters for additional RF testing and end-to-end integration.

Yet the location and the ecosystem around it seem just as important as cost. Links with Oulu university are unsurprisingly strong, and its academic reputation lures plenty of overseas talent. Veijo Kontas, a long-serving Nokia executive now in charge of system-on-a-chip strategy, says he has 43 different nationalities in his team. Rumana Yasmin, introduced to reporters on this week's tour, joined Nokia after completing studies in her native country of Bangladesh and then Oulu.

She describes the Finnish city as the "Silicon Valley of the north," and Pyykkönen also reflects on Oulu's broader ICT ecosystem of some 1,000 companies and about 20,000 people with relevant technology expertise. "That helps with collaboration," he said. At the opposite end of the scale, Nokia can also escape easily into the wild.

A bank of screens shows data from drones used at Nokia's outdoor testing area. (Source: Iain Morris/Light Reading)

About 35 kilometers outside Oulu is a vast, deserted area of woodland where a wandering moose might occasionally see a drone in flight or hear the roar of a car's engine. It is Nokia's outdoor test area, where technologies are unleashed after they have been prodded and poked in the torture chambers of OTAVA. Technicians are still sometimes dispatched there to drive wirelessly connected vehicles around an icy track.

But Nokia's preference, these days, is for internally built drones, operated remotely from a warm booth back in OTAVA. Lodged in dome-shaped containers (also remotely operated) when they are not in flight, they can generate accurate measurements on all manner of performance parameters. Data is fed back to the Oulu technicians and displayed across multiple screens.

Robot world

A short drive from the R&D facility is the Oulu factory, staffed by about 400 of the 3,000 local employees. Run by Mikko Nissi, it is where many of Nokia's mobile products, from baseband equipment through to radios, are first made before production is ramped up at other facilities. This means it also plays a role in spotting initial glitches and reporting back the details so they can be quickly addressed by the nearby R&D experts.

It does, nevertheless, handle some mass production for European markets, and its product lines are impressively automated. At the time of the media visit, two giant robot arms were pirouetting baseband circuit boards in perfect synchronization. An R2D2-like floor robot scurried back and forth along a central corridor, carrying electrical boxes from one place to another.

Giant robot arms make baseband equipment for Nokia at Oulu. (Source: Iain Morris/Light Reading)

Staff estimate the level of automation is about 75%. And roughly 70% of factory machines are now connected to a private 5G network that Nokia built. "We wanted to eat our own dog food," said one employee. Nissi encourages all staff to contribute ideas on operational improvements – what the Japanese refer to as Kaizen. About 1,500 are implemented every year to generate savings and boost efficiency, he told reporters.

Nokia is also using a cloud-based digital twin to aid real-time process management. The move has been accompanied by some investment in generative artificial intelligence, allowing employees to quiz a database on specifics. GPT-4, a large language model built by OpenAI, is the platform of choice. To ensure information is cordoned off from public view, staff say it is hosted in a "secure playground" provided by Microsoft.

Relocation

Nokia's future, though, lies elsewhere in Oulu. Currently under construction is a new campus measuring 55,000 square meters that Nokia plans to lease with forward funds provided by a finance partner. Built by YIT, a Helsinki-headquartered construction company, it will open in 2025 and eventually house about 1,500 employees. Of the existing facilities, only the OTAVA premises will be retained.

Today, it is literally a building site, off limits to anyone who lacks a hard hat, fluorescent jacket and steel-capped boots. Yet work is progressing fast. Artistic impressions show pristine communal areas and big open spaces. One important goal is to be fully carbon neutral at the new site. An energy station connected to the campus is being designed to support all its heating, cooling and electricity needs. It will feature a heat pump and energy storage system, as well as solar panels, and Nokia thinks it will be able to sell about 73,000 megawatt hours back to the Oulu district heating grid each year – enough to heat 20,000 apartments.

The main block of Nokia's new campus, due to open in 2025. (Source: Iain Morris/Light Reading)

By then, the Finnish company will pray its market has picked up. Hit by a shortfall in customer spending this year, Nokia recently said it would have to cut up to 14,000 jobs to safeguard the business, a figure that would equal about 16% of today's total. R&D is unlikely to emerge unscathed from this process, but CEO Pekka Lundmark will know that deep cuts would badly hurt Nokia's competitiveness. Under Rajeev Suri, his predecessor, Nokia was heavily criticized for slashing annual R&D expenditure, which fell by €500 million (US$543 million), to €4.4 billion ($4.8 billion), between 2016 and 2019.

If there is nervousness within the Oulu ranks, it was well hidden from the media this week. The overriding impression is of a team passionate and enthusiastic about its role. Employees proudly refer to themselves as Nokians. And it is easy to agree with them – after just a day among the brainiacs of Oulu – that mobile tech is increasingly undervalued as a commodity. Whatever one's view of the market dynamics, that label does not obviously suit a thing so extraordinarily complex.

Disclaimer: The trip to Oulu that formed the basis of this story was funded by Nokia.

About the Author(s)

You May Also Like